Northrop Grumman is one of the world’s premier aircraft providers with a proud heritage of designing and building iconic aircraft like the world’s first sixth-generation stealth bomber, the B-21 Raider, the B-2 Spirit and the F-14 Tomcat. This history complements the company’s expertise as a key manufacturer of the fifth-generation F-35 Lightning II center fuselages. And now, through new partnerships with international industry, Northrop Grumman is poised to continue a track record of advanced manufacturing excellence to meet the demand from allies for cutting-edge airpower capabilities. The company’s commitment to innovation is unwavering, and pioneering technologies like the IAL are continuously integrated into future production lines. By sharing advanced technology and proven aeronautics expertise with Rheinmetall at the IAL facility in Germany, Northrop Grumman is reaffirming its commitment to working with local partners, bringing its capabilities and pioneering technology to an ever-growing number of international customers.

International demand for fifth-generation F-35 fighter aircraft has increased the need for additional fuselages. To help meet this need, Northrop Grumman partnered with Rheinmetall AG to establish a second center fuselage IAL facility in Weeze, Germany. Following a groundbreaking ceremony last month, Rheinmetall is building the facility and Northrop Grumman will share manufacturing technologies and expertise to enable production of F-35 fuselages there by 2025. Starting in 2027, the Weeze IAL facility is expected to produce up to 30 fuselages per year. Combined, both IAL facilities will be able to produce up to 185 center fuselages yearly to meet the F-35 program’s future requirements. “The groundbreaking marks a significant new chapter in the production of a fifth-generation, multi-role fighter for the United States and its allies to protect our sovereign interests and defend freedom around the globe,” said Glenn Masukawa, vice president and F-35 program manager, Northrop Grumman. “Our collaboration with Rheinmetall exemplifies how we expand local growth and opportunities to establish a global footprint for F-35.” The collaborative effort leverages Rheinmetall’s experience with the German Armed Forces and European industry while fostering critical skills and energizing the region’s economy with high-tech job opportunities.

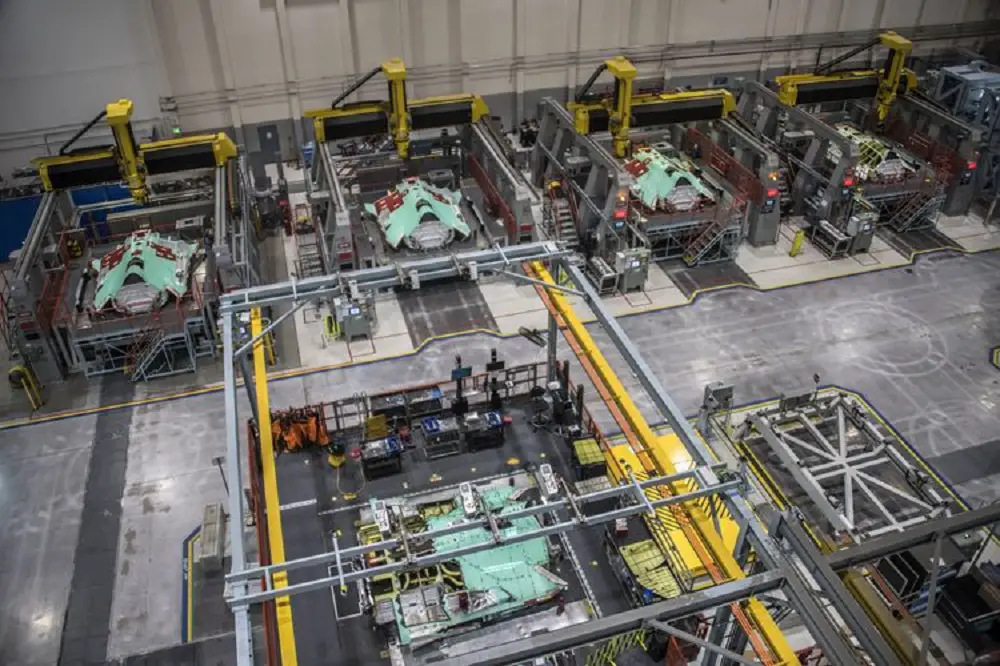

At its F-35 center fuselage Integrated Assembly Line (IAL) in Palmdale, Calif., Northrop Grumman’s deep history of aircraft design, technological prowess and innovative approaches to military aircraft production culminated in a first-of-its kind defense manufacturing facility that pairs new automated tools and robotics with a highly skilled workforce. Northrop Grumman designed and created the IAL using innovations from the automobile industry as a guide, marking the first time automotive and aircraft technologies were integrated at such scale. The IAL is comprised of over 3,000 parts, scalable to 115 assembly positions and capable of completing one center fuselage every 30 hours. The assembly line features unique manufacturing technologies — exclusive to or pioneered by Northrop Grumman. The IAL maximizes robotics and automation, providing additional capacity and assembly capability to achieve high rates of production, while meeting engineering tolerances not easily achieved manually. Since coming online in March 2011, the IAL has produced over 1,100 center fuselages for all three variants of the F-35 Lightning II. In 2022, Northrop Grumman delivered the 1,000th center fuselage produced at the IAL.

Northrop Grumman has a proud legacy of supporting the defense needs of allied partners through capabilities, such as NATO Air Ground Surveillance, E-2D Advanced Hawkeye and the Integrated Air and Missile Defense Battle Command System. Collaboration with international industry partners, like Rheinmetall, underscores Northrop Grumman’s commitment to the European region and to support a stronger alliance for mutual defense. Northrop Grumman has manufactured some of the world’s most advanced aircraft and innovations like the IAL are continuously incorporated into future production lines. Sharing the company’s advanced technology and proven aeronautics expertise with Rheinmetall at the IAL in Germany is reflective of our commitment to work with local partners to bring our capabilities and pioneering technology to a growing number of international customers.