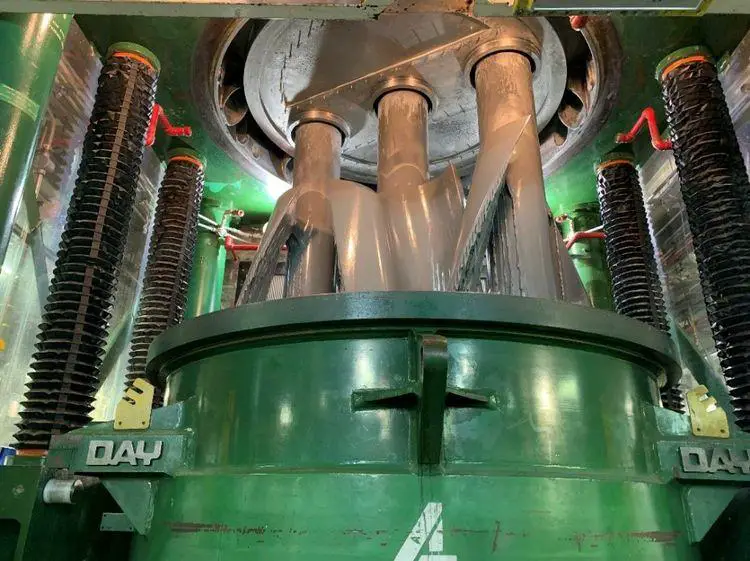

Northrop Grumman Corporation completed the first full-scale mix of the solid rocket motor propellant for its Next Generation Interceptor (NGI). This successful full mix helps ensure the solid rocket motors supporting the Northrop Grumman and Raytheon Technologies’ NGI solution are on track to complete qualification via static test. The successful operation was completed using the company’s remote automated solid rocket motor manufacturing facilities in Bacchus, Utah. The unique, automated, 1,800-gallon mixers, combined with the company’s proven automation capabilities, enables consistent and safe production of high performing solid rocket motors for government and commercial customers, including the Missile Defense Agency.

The Missile Defense Agency (MDA) leads the development of anti-ballistic missiles for America. The Next Generation Interceptor (NGI) is a MDA program to upgrade the kill vehicles for the ground-based interceptors, with different vendors, Lockheed Martin and Northrop Grumman competing. They are tasked with meeting more complex threats than those met by the EKV. There will be more near-term technology improvement to the Ground-Based Interceptor (GBI) during a longer-term process for NGI to meet more complex threats. The GBI is the anti-ballistic missile component of the United States’ Ground-Based Midcourse Defense (GMD) system. As part of the first phase, the Missile Defense Agency allocated $7.6 billion in contract money to Northrop Grumman (in partnership with Raytheon) and Lockheed Martin to upgrade aging ground-based interceptors (GBIs). The NGIs are to be fielded by 2027 or 2028.

The tracking sensors and computers (whether they be C2BMC, or IBCS, etc.), which follow the parabolic trajectories of the ballistic missile, count down the time to go needed before impact of the interceptor’s kill vehicle with the targeted ballistic missile. When the tracking sensors and computers determine there is enough time to kill the ballistic missile without using the third booster stage, the kill vehicle can maneuver using its thrusters to hit the targeted ballistic missile without the third stage. This increases the probability of kill, for the kill vehicle, which can instead more closely follow the targeted missile, rather than its projected parabolic trajectory. As described, the NGI is being engineered to handle more complex situations to be able to hit maneuverable targets.