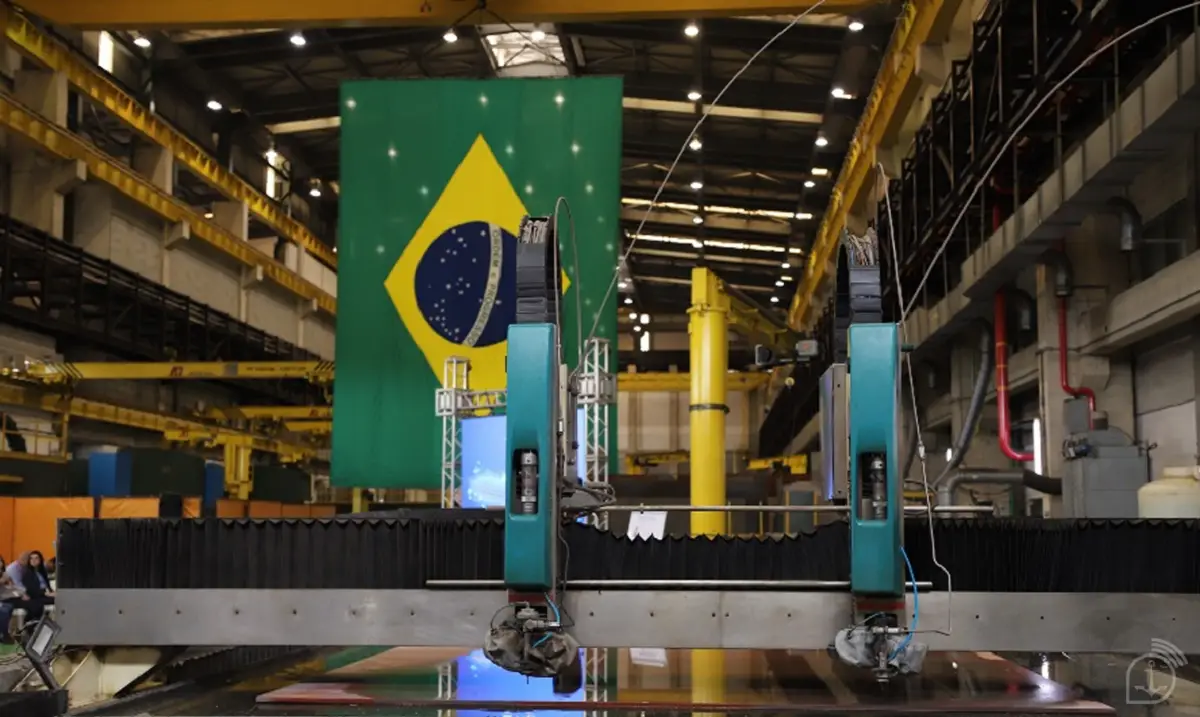

On October 4th, the Brazilian Navy (Marinha do Brasil, MB) marked a historic moment with the Cutting Ceremony of the First Sheet of the Qualification Section of the Conventionally Armed Submarine with Nuclear Propulsion (Submarino Convencionalmente Armado com Propulsão Nuclear, SCPN) at the Itaguaí Naval Complex (CNI). This significant event, organized by the Navy’s General Directorate of Nuclear and Technological Development (DGDNTM), signifies a major step forward in the construction of the SCPN. Presided over by Admiral Petronio Augusto Siqueira de Aguiar, Director General of Nuclear and Technological Development of the Navy, the ceremony saw the presence of Admirals Flávio Augusto Viana Rocha and Alexandre Rabello de Faria, among other esteemed guests. This marked the commencement of the construction of the structure forming the Qualification Section, a crucial element in the submarine’s development. Civil and military authorities, as well as representatives from the nuclear, academic, and business sectors, were also in attendance.

Rear Admiral (EN) Marcio Ximenes Virgínio da Silva, Manager of the Modular Submarine Procurement Project, explained the importance of the Qualification Section. Though it won’t be part of the submarine itself, it plays a vital role in approving the construction process and, subsequently, certifying the Shipyard for naval environment construction. The initial steel cuts create “souls,” which will form a series of compartments joined to the plating, eventually composing the Qualification Section. This phase involves various activities beyond the core construction, such as logistical considerations and process analysis, given the section’s substantial weight of approximately one hundred tons. The SCPN, a centerpiece of the Submarine Development Program, represents the Navy’s most ambitious strategic initiative. It enables Brazil to design and construct conventional and nuclear-powered submarines, emphasizing technology transfer, equipment and systems nationalization, workforce training, and significant job creation.

“The Qualification section will make it possible to assess the capacity, unique in the southern hemisphere, of building a Conventionally Armed Submarine with Nuclear Propulsion. Thus, this moment marks the beginning of the shipyard’s search for its qualification with the construction process to be approved, in order to allow the beginning of construction of the Submarine in the future,” Rear Admiral (EN) Ximenes emphasized.

“We sail, duly qualified, towards the achievement of a dream, the Conventionally Armed Submarine with Nuclear Propulsion, a legitimate aspiration for a Country with a vocation to guarantee its sovereignty, defend its wealth, and its people,” Admiral Petronio Augusto Siqueira de Aguiar stated. Admiral Petronio highlighted the extraordinary technological leap that the Program represents for Brazil, significantly enhancing the defense sector’s strategic importance in safeguarding the nation’s sovereignty and resources.

Currently, the project involves approximately 1,500 workers, including military and civilian personnel. However, the program has the potential to generate up to 24 thousand direct jobs and 40 thousand indirect jobs. Brazil is taking a monumental step to elevate its technology to the level of countries like France, the United States, China, England, and Russia. With the Brazilian Navy commanding this modern submarine, it will have the capability to protect the vast Brazilian coastline effectively. Universities and research institutes involvement ensures the dissemination of nuclear sector knowledge in the country, preventing the “brain drain” and retaining intellectual capital within Brazil. This momentous milestone in Brazil’s naval history underscores the nation’s commitment to technological advancement and national security, positioning it among the world’s leading naval powers. The SCPN project not only holds the promise of enhanced defense capabilities but also the creation of thousands of jobs and the fostering of domestic expertise in cutting-edge technology.