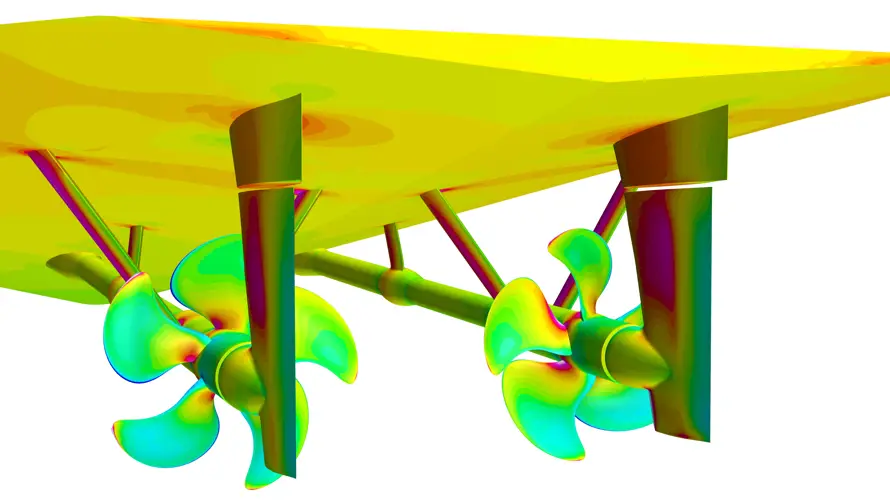

Kongsberg Maritime has concluded a research programme that shows its Promas propeller and rudder system can deliver a host of benefits for naval platforms including significant fuel savings, greater range and improved manoeuvrability. Originally designed for commercial ships, Promas combines rudder and propeller into one propulsion system. Most naval twin-screw vessels use conventional rudders placed off-centre from the shaft centreline. Promas can deliver fuel savings of more than 5% which can translate into increased range, boosting the capability of naval platforms.

The research, carried out by Kongsberg’s Hydrodynamic Research Centre (HRC), has shown that naval vessels relying on traditional rudder and propeller systems can increase their efficiency and manoeuvrability with the adoption of the Promas propeller and rudder system. The HRC tested and compared the Promas bulb-rudder system, and the conventional off-centre rudder system used by navies on a typical naval aft ship dummy design. The dummy design consisted of an open shaft configuration with V-bracket and high shaft inclination angle to produce a typical wake field for a naval twin screw vessel.

Patrik Kron, Kongsberg Maritime’s Chief of Naval Systems, said: “We’ve known for many years how Promas brings a quick improvement in efficiency for commercial operators, and this latest research demonstrates how these benefits can be offered to our governmental customers. By being able to demonstrate an improved efficiency of around 6%, for navies this means their vessels are able to extend their range, something which can be crucial on longer missions. “We know there is a large market for grey and light grey ships operating up to 25 knots, so our initial research has focussed on that speed range, but we’re continuing our research to consider how Promas could enhance the operational capability of combatants which operate at up to 30 knots”.

The tests compared propulsive efficiency, rudder forces, cavitation inception speed, cavitation, pressure pulses, and noise levels between Promas and conventional navy propulsion for ship speeds up to 25 knots. At 25 knots, the Promas system reduced power consumption by 6%. The rudder forces with Promas are also much higher. The system demonstrated less drag at small rudder angles and a higher lift at larger angles than a conventional navy system. This improves slow speed and harbour manoeuvring. Kongsberg Maritime supplies technology, equipment and services needed for sustainable maritime operations today and in the future.