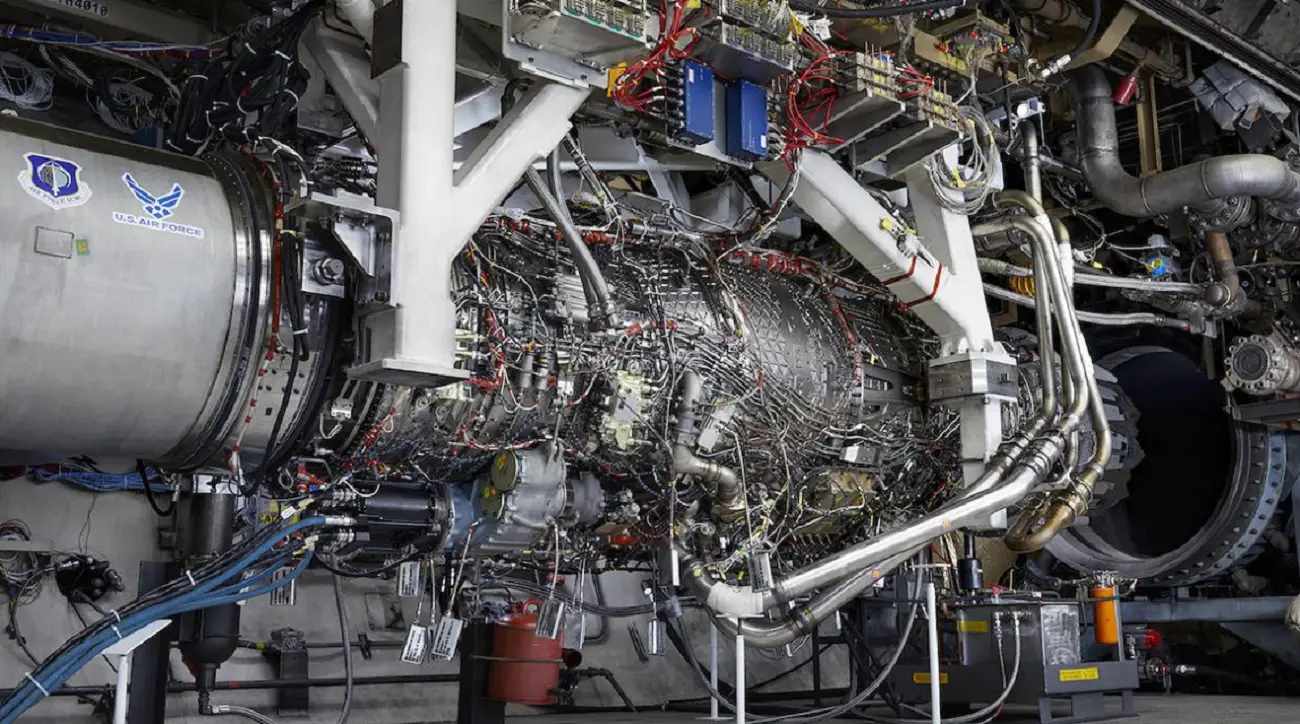

GE Aerospace announced that its XA100 engine successfully completed additional testing, in coordination with the U.S. Air Force, after completing all Adaptive Engine Transition Program (AETP) testing last year. With continued positive testing results as well as Congressional support for advanced engine development, GE Aerospace is moving this cutting-edge technology closer to the hands of America’s warfighters, with learnings that could support the Next Generation Adaptive Propulsion (NGAP) program.Supported by over 400 engineers, the second XA100 engine underwent its third round of testing at GE Aerospace’s Evendale, Ohio facility to validate minor design improvements informed by previous testing conducted in 2022; further solidify the engine’s detailed design and digital models; and accelerate adaptive propulsion development and associated technologies for sixth-generation applications through scenario-specific testing.

“With a third round of testing, GE Aerospace has proven again our place as the industry leader in adaptive cycle engines,” said GE Aerospace’s Defense & Systems President and CEO Amy Gowder. “Recent Congressional support for advanced engine development in the defense appropriations bills will help continue our progress as we work to bring this revolutionary technology forward for U.S. warfighters.”

“Our XA100 engine, already the most advanced combat engine ever developed, is now one of our most tested prototypes. This third round of testing represents our commitment to go above and beyond to ensure our military is ready with the revolutionary capabilities they need, and we are pleased with the learnings it has provided for our work today and in the future,” said GE Aerospace Vice President and General Manager for Advanced Defense Products David Tweedie.

GE Aerospace’s XA100 engines have now logged hundreds of hours of rigorous, system-level performance and operability testing, providing the company with unprecedented knowledge of the adaptive cycle engine architecture and the transformational capabilities it offers. The XA100 engine is estimated to provide pilots up to 25 percent greater fuel efficiency and 30 percent greater range to help the U.S. ensure its airpower advantage in contested environments. GE’s XA100 is unlike any engine in jet propulsion history. It’s engineered to switch between high-thrust and high-efficiency modes, allowing it to adapt to just about any situation a military jet could encounter in the air. In December 2020, it became the first ever flight-weight, three-stream adaptive cycle engine to fire up. Additionally, the XA100 provides twice the thermal management capacity compared to current fighter engines, which enhances the capabilities of onboard electronics and sensors for this decade and beyond.

GE Aerospace, a subsidiary of General Electric, is headquartered in Evendale, Ohio, outside Cincinnati. GE Aerospace is among the top aircraft engine suppliers, and offers engines for the majority of commercial aircraft. GE Aerospace is part of the General Electric conglomerate, which is one of the world’s largest corporations. The division operated under the name of General Electric Aircraft Engines (GEAE) until September 2005, and as GE Aviation until July 2022. GE Aerospace’s main competitors in the engine market are Pratt & Whitney and Rolls-Royce. GE Aerospace is a world-leading provider of jet engines, components and systems for commercial and military aircraft with a global service network to support these offerings. GE Aerospace and its joint ventures have an installed base of more than 40,000 commercial and 26,000 military aircraft engines, and the business is playing a vital role in shaping the future of flight