United Technologies Corp., Pratt & Whitney Military Engines, East Hartford, Connecticut, is awarded a $455,524,124 modification (P00016) to a previously awarded fixed-price-incentive-fee, cost-plus-fixed-fee contract (N00019-18-C-1021). This modification provides for non-recurring engineering and tooling in support of the lot 14 production and delivery of 32 F135-PW-100 propulsion systems and one F135-PW-600 propulsion system for F-35 Joint Program Office non-Department of Defense (DoD) participants.

Fiscal 2018 aircraft procurement (Marine Corps, and Navy); fiscal 2019 aircraft procurement (Air Force); and non-DoD participant funds in the amount of $413,030,550 are being obligated at time of award, $13,932,222 of which will expire at the end of the current fiscal year. Work will be performed in East Hartford, Connecticut (97%); Indianapolis, Indiana (2%); and Bristol, United Kingdom (1%), and is expected to be completed in April 2022. The Naval Air Systems Command, Patuxent River, Maryland, is the contracting activity.

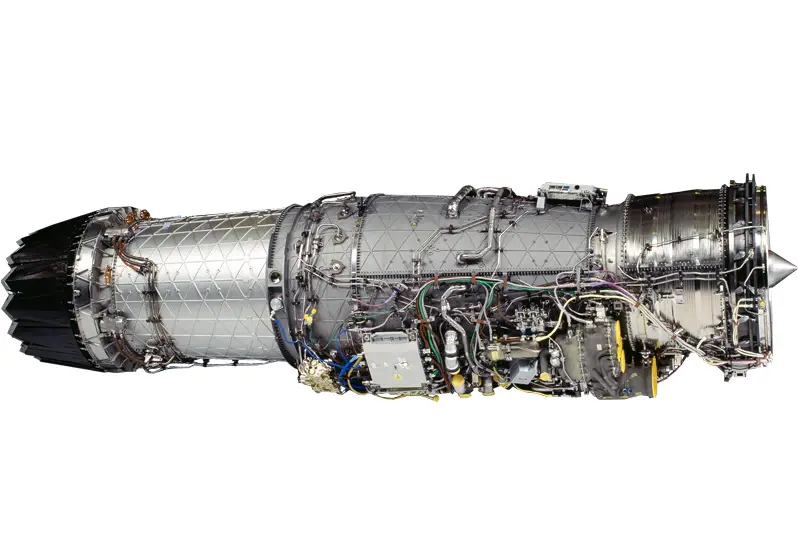

Pratt & Whitney’s F135 propulsion system powers all three variants of the F-35 Lightning II fighter aircraft – the F-35A CTOL (Conventional Takeoff and Landing), F-35B STOVL (Short Takeoff and Vertical Landing) and F-35C CV (Carrier Variant). The affordable, available, adaptive F135 is the world’s most advanced fighter engine, delivering more than 40,000 lbs. of thrust and unmatched advances in safety, design, performance, and reliability. The F135 has evolved from the proven F119 engine, which exclusively powers the U.S. Air Force’s F-22 Raptor, and features best-in-class single-engine reliability, fifth generation stealth capabilities as well as advanced prognostics and health management systems.

The F-35 is the first truly international fighter aircraft development program – developed to serve the United States, the United Kingdom, Italy, the Netherlands, Turkey, Canada, Australia, Denmark, Norway and other allied nations. Pratt & Whitney has partnered with the best aerospace companies in the world to manufacture critical components of the F135, with the goal of producing the most advanced propulsion system while providing value to F-35 customers around the world. Since powering the F-35’s first flight in December 2006, the F135 has maintained high readiness levels that have enabled the program to meet flight test objectives and support operational requirements for all three aircraft variants.