The Abu Dhabi (hull number P 191) is anti-submarine corvette for the United Arab Emirates (UAE) Navy. Designed and built by Italian shipyard…

Howitzer

ShinMaywa US-2 Amphibious Aircraft

The ShinMaywa US-2 is a Japanese large STOL amphibious aircraft manufactured by Japan-based ShinMaywa Industries. Designed for air-sea rescue missions, the US-2 is…

Steiner ICS Combat Sight

Steiner’s new “Intelligent” Combat Sight (ICS) integrates a laser rangefinder and a ballistic calculator into a rugged and compact tactical weapons sight. It…

Antonov An-70 Military transport aircraft

The Antonov An-70 is a four-engine medium-range transport aircraft, and the first aircraft to take flight powered only by propfan engines. It was…

Umkhonto Ground-based Launcher (GBL)

Umkhonto ground-based launcher (GBL) is a mobile surface-to-air missile (SAM) vertical launching system being developed by Denel Dynamics primarily for the South African…

United States Second Fleet

The United States Second Fleet is a numbered fleet in the United States Navy responsible for the East Coast and North Atlantic Ocean….

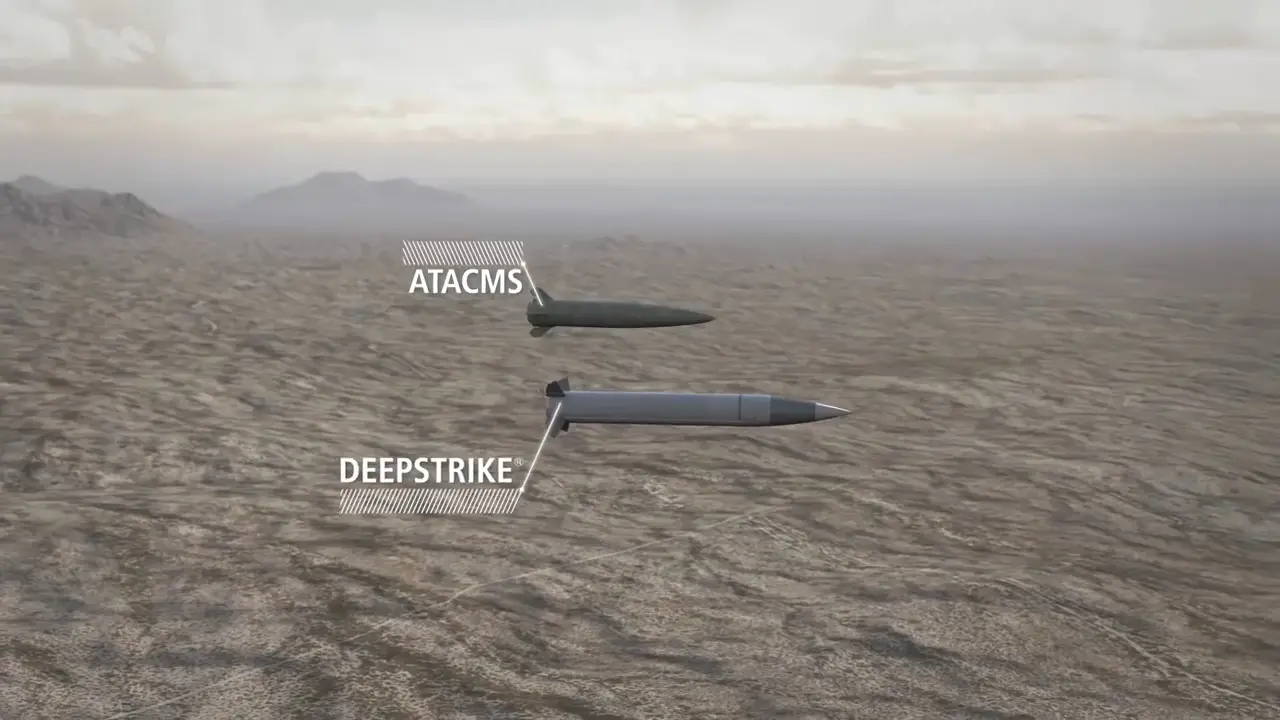

Raytheon DeepStrike Missile System

In March 2016, Lockheed Martin, Boeing, and Raytheon announced they would offer a missile to meet the U.S. Army’s Long Range Precision Fires…

155 mm ShKH Zuzana 2 Self-propelled Howitzer

Zuzana 2 155 mm Self-propelled Gun Howitzer is a Slovak artillery system with a 45-caliber gun and automatic loader for loading of both…

French Army Caesar self-propelled howitzer

In December 2004, Giat was awarded a contract for 72 Caesar systems to equip eight land artillery batteries of the French Army, to…