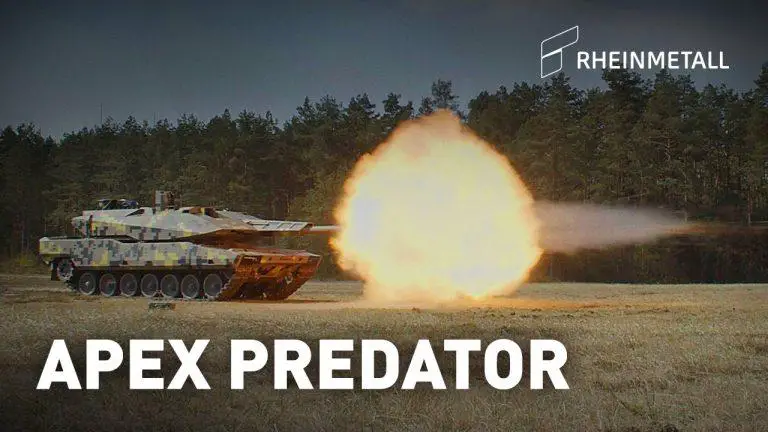

British Army soldiers are a step closer to getting their hands on one of Europe’s most lethal tanks, as the latest Challenger 3…

Recent Posts

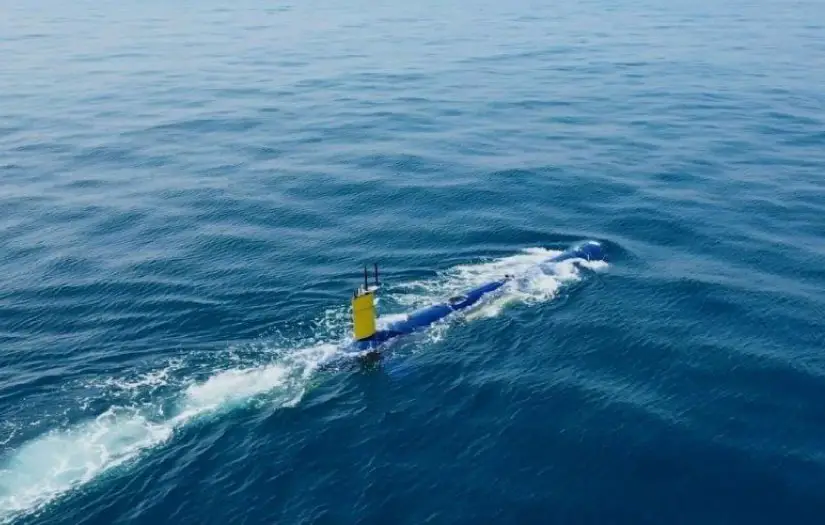

First Anduril’s Ghost Shark Extra-large Autonomous Undersea Vehicle Debuts in Australia

Anduril, the Royal Australian Navy (RAN), the Advanced Strategic Capabilities Accelerator (ASCA) and Defence Science and Technology Group (DSTG) are pleased to unveil…

US Air Force Test Pilot School and DARPA Announce First Artificial Intelligence Dogfight

The U.S. Air Force Test Pilot School and the Defense Advanced Research Projects Agency were finalists for the 2023 Robert J. Collier Trophy,…

MilitaryLeak.COM

US Army’s Mid-Range Capability (MRC) Makes Its First Deployment in the Philippines

In a historic first, the 1st Multi-Domain Task Force successfully deployed the Mid-Range Capability, or MRC, missile system to Northern Luzon, Philippines, on…

KDNS France Unveils New Upgrade of DCLR Tank Recovery Vehicle

KNDS (KMW + Nexter Defense Systems) France has recently introduced the latest iteration of the Leclerc Tank recovery variant, known as the DCLR…

UK Ministry of Defence Signs Contract for Saab Instrumented Live Training Capability

Saab has signed an initial three-year contract with the UK Ministry of Defence, for the provision of support to Live Simulation systems with…

US State Department Approves Sale of Basler BT-67 Aircraft and Logistics to Argentina

The US State Department has made a determination approving a possible Foreign Military Sale to the Government of Argentina of Basler BT-67 Aircraft…

Baykar KEMANKES 2 Mini Cruise Missile Completes First Firing Test

Turkish leading defense firm, Baykar, has completed the first firing test of the KEMANKES 2 Mini Intelligent Cruise Missile, developed indigenously and originally,…

Northrop Grumman Expands Royal Australian Air Force MQ-4C Triton Support Team

Northrop Grumman Australia (NYSE: NOC) has signed a contract with L3Harris Corporation (L3HCA) for the operation and maintenance of command-and-control systems aboard Australia’s…

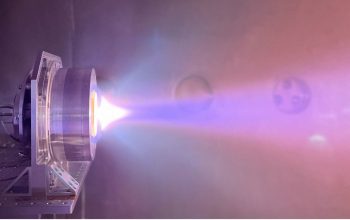

Aerojet Rocketdyne and Kratos Successfully Hot-fire Zeus 2 Advanced Large Solid Rocket Motor for Hypersonic Test

Aerojet Rocketdyne, an L3Harris Technologies company, successfully hot-fired the second of two high-performance large solid rocket motors at its Camden, Arkansas site. The…