The Honeywell/ITEC F124 is a low-bypass turbofan engine derived from the civilian Honeywell TFE731. The F125 is an afterburning version of the engine. The engine began development in the late 1970s for the Republic of China (Taiwan) Air Force AIDC F-CK Indigenous Defence Fighter (IDF), and it first ran in 1979. The F124/F125 engine has since been proposed for use on other aircraft, such as the T-45 Goshawk and the SEPECAT Jaguar, and currently powers the Aero L-159 Alca and the Alenia Aermacchi M-346. The F124 has a rather unusual design for a two spool gas turbine engine, using both axial and centrifugal compressors in its high-pressure compressor. There are currently only three production variants of the engine, although several more have been proposed throughout its lifespan.

The Honeywell F124 turbofan engine has what it takes to power today’s most advanced military jet trainers and light combat fighters – maximum performance, reliability and availability. No wonder the F124 was Leonardo DRS’ choice to power the T-100 trainer, the company’s entry in the U.S. Air Force T-X trainer competition. The engine already flies on the Leonardo M346 Master, the most advanced military trainer in service, and on a variety of other light fighters and unmanned vehicles. In all, the F124/F125 family of engines has more than 1 million operating hours to its credit. The F124 has the highest thrust-to-weight ratio in its class, thanks to a unique single-stage design that maximizes engine performance.

The F124 engine is fundamentally a low bypass, two spool engine (meaning that there are two rotational shafts, a high-pressure shaft and a low-pressure shaft). The fan/low-pressure compressor section is made of three stages with titanium blades. The first stage has 30 un-shrouded blades,and the overall pressure ratio for the three stage fan section is 2.5:1. Some of the air is bypassed (Bypass ratio of 0.472:1), and the rest is fed to the high-pressure compressor section.The high-pressure compressor (HPC) of the F124 is a fairly unusual design among turbofan engines; it employs both axial and a centrifugal compressors in a single design. There are four axial stages that lead to a fifth centrifugal stage. All the blades and the impeller are made from titanium.

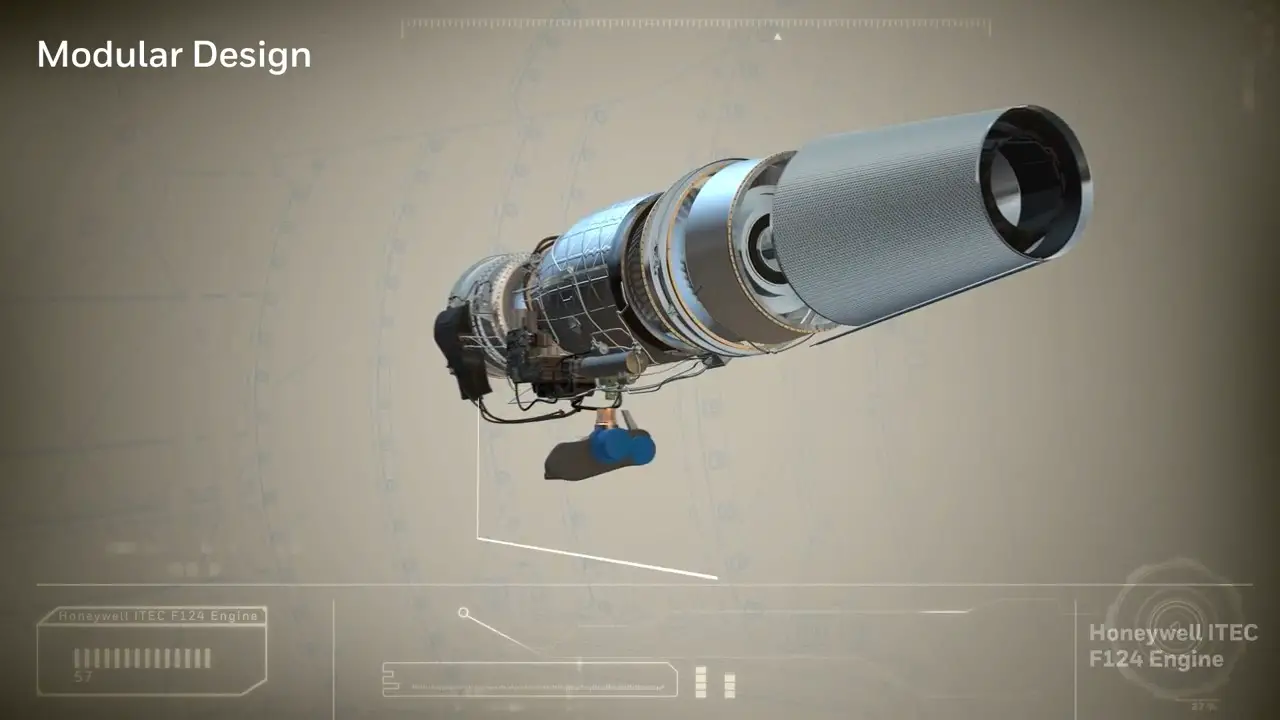

The engine features advanced Full Authority Digital Electronic Control (FADEC) and an integrated Engine Monitoring System (EMS) to keep tabs on engine health, monitor usage and streamline troubleshooting. Modular design makes the engine faster and easier to repair, enabling maintenance teams to put training instructors and student pilots where they belong, back in the air, quickly and efficiently. Safety is paramount in the flight training world and the T-100 provides an additional safety margin by using two F124 engines. The F124 offers all this and more, backed by the global resources of Honeywell and a reputation earned in producing some of the world’s best turbine engines over more than six decades.

Honeywell F124 Turbofan Engine

Honeywell F124 Turbofan Engine